How Does an LED Work?Posted by Stephen Shickadance in How Solar Lights Work.

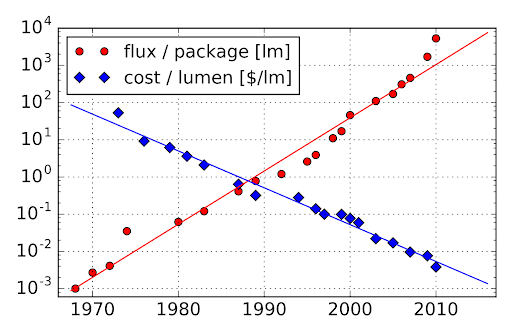

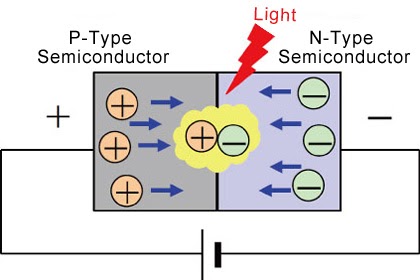

LEDs operate similarly to photovoltaic cells, except that the transfer of electrons is reversed of how photovoltaics generate electricity from solar energy. The p/n junction with a semiconductor is still at work here, where the “p” energy band has an abundance of electrons and the “n” energy band has an abundance of electron holes, or atoms without electrons in their electron shells. When you connect power to an LED, the electrons in the “p” band get excited and jump the band gap, where they fill electron holes called the junction point. When they fill the junction point, they emit a photon, or unit of light. This is called electroluminescence, the foundational phenomenon behind how an LED functions. Electroluminescence is based upon the properties of the semiconductor in the LED. For instance, an early LED (that produced visible red light) used gallium arsenide. LEDs that produce different colors use different semiconductors—such is the case with white LEDs. How to Get White Light from an LEDIn the mid-90s, blue LEDs were invented from Professors Isamu Akasaki, Hiroshi Amano, and Shuji Nakamura. Blue LEDs were difficult to invent because they required a specific semiconductor in order to emit photons in the proper wavelength for blue light--it turns out that Gallium Nitride was the secret ingredient needed for blue LEDs. This invention was groundbreaking because producing white light from an LED was closer to reality. It finally became one when a phosphorus layer was applied to the LED lens. White light LEDs paved the way for developments into newer technologies such as clearer televisions, more efficient light bulbs, and, of course, LED light fixtures for solar street lights. We’ve seen improvements since the invention of white LEDs primarily in efficiency and longevity. White light LEDs have seen exponential increases in efficiency because of what’s known as Haitz’s Law. This law outlines the cost of LEDs vs efficiency on a logarithmic scale, thus demonstrating how LEDs have grown in efficiency and dropped in price over time.

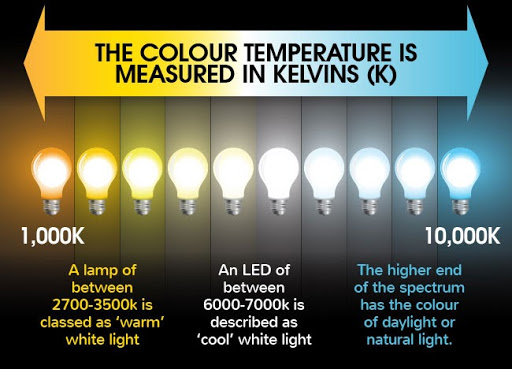

LED Standards for a ManufacturerColor TemperatureWhite LEDs are the result of a phosphorus layer on top of a UV-emitting diode, but the phosphorus layer often determines the color temperature of the light. A common color temperature for LEDs is 4,000K, or a “cool white,” but this can be adjusted based on the needs for the client.

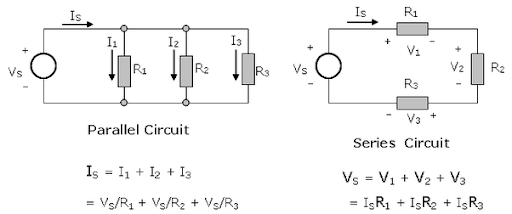

Color temperature for lighting is measured on the Kelvin scale between 1,000K to 10,000K, with 1,000 a much more “warm” color and 10,000K being a very “blue-white” light. LED Manufacturer PioneersOne of the biggest pioneers of modern-day LEDs is the company CREE, an industry leader in light development. CREE LEDs are used in high-quality light fixtures because they maintain very high standards. Founded in July of 1987, CREE was one of the first lighting manufacturers to synthesize silicon carbide, a compound which is heavily used in LEDs. CREE is a very common name in the LED industry, so you can be certain you’re getting quality LEDs when you choose a solar lighting manufacturer that uses products out of CREE’s warehouses. Fixture StandardsTwo standards of which are the most sought-after, for LEDs are efficiency and longevity. Current standards for LEDs in high-quality fixtures include 130 lumens per watt and 50,000 hours of runtime until an LED drops to 70% of its original brightness. Of course, that’s not all aspects of lights that point to quality. LEDs that are connected in a series circuit--meaning a singular connection between all lights--are more likely to fail because if one light burns out, they will all burn out. A parallel circuit connects each light to the main power source so if one LED fails, the rest continue to function.

Be sure to ask your manufacturer what circuitry is used in their light fixtures. If they use a series circuit, your entire light fixture depends on the functionality of all LEDs in the circuit. You won’t see a full 50,000 hours of runtime with a series circuit. LED Light Lenses: Where You Need QualityNow let’s look into LED light lenses, what a quality lens is made of, and how they disperse light. Not every solar light will adhere to these standards, but this knowledge should steer you away from the pitfalls of purchasing sub-par solar lighting products. The distribution and quality of light depend on the quality of the LED light lens that it feeds through. There are two main aspects of lenses which feed into the patterns of light on the ground--material and distribution type. Material of LensesLED light lenses need to be made of quality material. Some manufacturers use thin plastic to cover their LEDs. Plastic won’t last very long for LEDs that are meant for all-weather conditions. Acrylic is the most widely used material for LEDs. Ensure your manufacturer has thick, sturdy LED covers to withstand heat and volatile weather, or else the lenses will warp and shorten the lifespan of your investment. Distribution Types of LEDsLEDs are arranged in different patterns for their fixtures. They’re named Type I through V. Here are the differences between them. Type IType I Distribution is great for sidewalks and narrow walkways. Generally, this kind of light distribution is centered above the walkway for maximum light exposure. Type IIThis distribution type is similar to I, except that it’s meant for walkways that are a little wider. The lateral width is typically about 25 degrees. This is more popular than a Type I. Type IIIThis distribution type can be found in roadways and parking lots where the light needs to illuminate a much larger area with the light set off to the side. The lateral width is set to about 40 degrees with this type. Type IVThis type is (once again) slightly larger, but best fit for lighting the sides of buildings and lots or very wide roadways. Typically, they’ll be set at a lateral width of 60 degrees. Type VThis distribution has the same light intensity in all directions and is typically meant for large, sprawling parking lots or intersections where light is needed in all directions. A variation of this is VS which casts the light in a square pattern as opposed to circular to give the light a more defined edge. Lambertian ReflectanceLambertian Reflectance is a property that defines an ideal "matte" or diffusely reflecting surface. A basic example of reflectance—snow or light concrete reflects better than black asphalt. Beam AngleBeam Angle is the angle at which light is distributed from a light source. The specific degree measurement from a lamp varies depending on the manufacturer, but a beam angle falls under four categories:

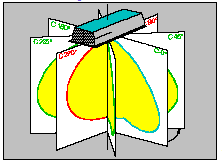

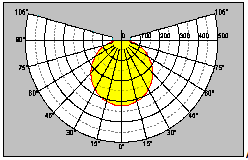

Luminous Intensity Distribution PatternThis pattern shows the direction and intensity of the light from the light source. Two graphs common in displaying the light patterns are called the plane system and the polar curve.

Plane

Polar Spectral Power DistributionA spectral power distribution is a graph of the energy levels of a light source through a range of wavelengths of light.

For this particular graph, the light source has a color temperature of 5000K but the power distribution shows where the actual energy levels lie. This shows the spectral colors that generate a color temperature of 5K. ConclusionLEDs are fantastic little devices of power and the technology behind them is surprising. They’re much more resilient than incandescent bulbs since there aren’t any filaments that “burn out.” This fact is one of the fundamental reasons why they’re used in commercial lighting today. If you're interested in a commercial lighting project, please drop a line. If you'd like to learn plenty more, we have a new, free solar lighting guide for review and download.

How Solar Lights Work

|

ArchivesNo Archives Categories

Want More Info? |

LATEST NEWS & ARTICLES